In any factory or industrial setting, downtime can be costly—not just in terms of lost production, but also in terms of potential damage to equipment and safety risks. Preventative maintenance and quick repairs are crucial to maintaining smooth operations. One of the keys to achieving this is having the right MRO (Maintenance, Repair, and Operations) supplies on hand.

MRO supplies are the tools, equipment, and materials that help keep machinery in top condition, ensure worker safety, and ensure compliance with industry regulations. Below are the 10 must-have MRO supplies that every factory needs to keep operations running efficiently and safely.

1. Lubricants and Oils

Why It’s Essential: Proper lubrication of machinery and moving parts is vital to reduce friction, prevent overheating, and extend the lifespan of your equipment. Lubricants and oils are essential for ensuring smooth operation and preventing wear and tear that could lead to breakdowns.

Must-Have Products:

Multi-purpose oils for general equipment

High-temperature greases for machinery running at extreme temperatures

Chain oils and lubricants for conveyors or motors

By keeping a variety of oils and lubricants on hand, maintenance teams can quickly address any lubrication needs and keep machines running smoothly.

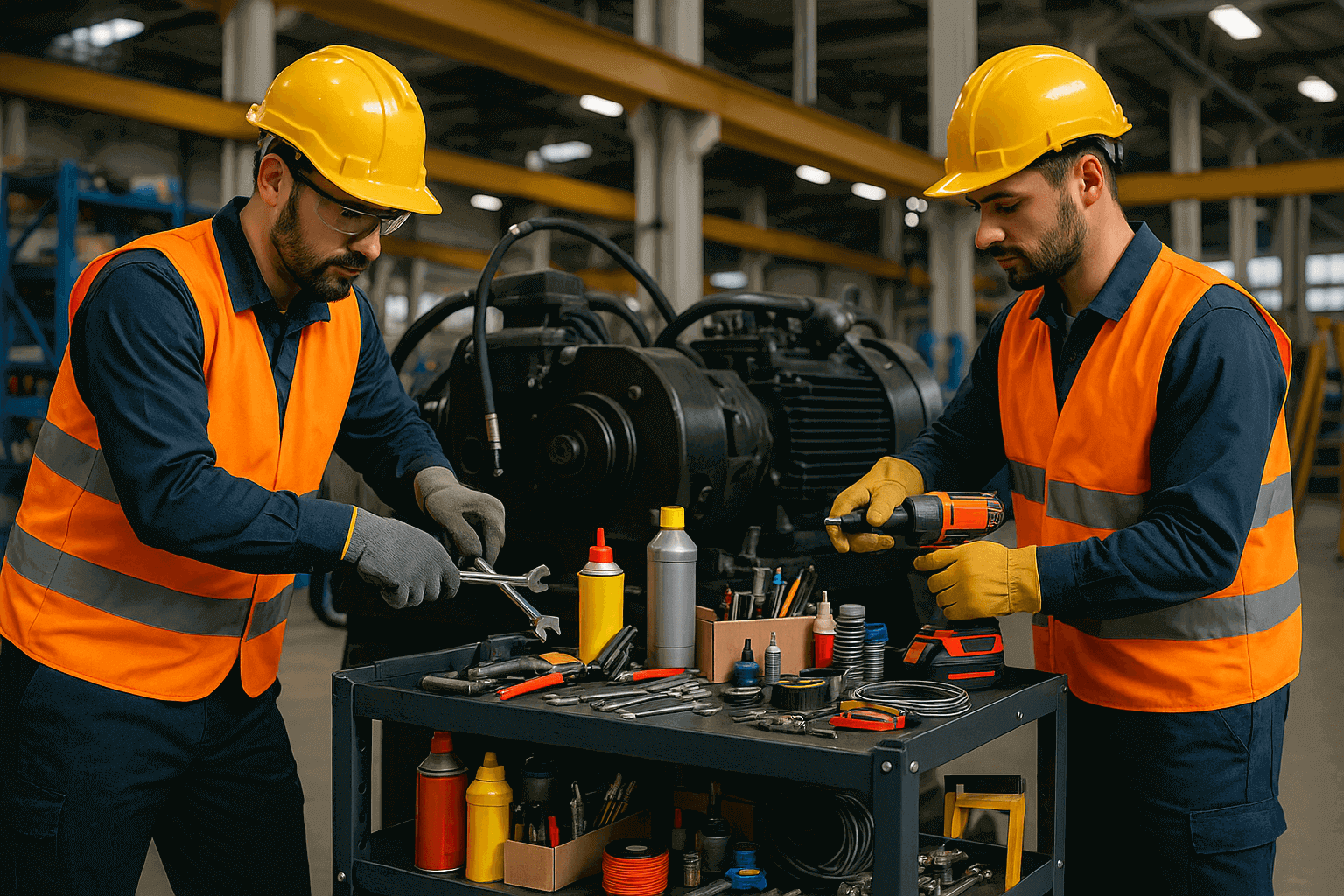

2. Hand Tools

Why It’s Essential: Hand tools are the backbone of any maintenance team. They are needed for everyday tasks such as tightening bolts, replacing parts, and performing minor repairs. Without the right hand tools, even simple tasks can become time-consuming and difficult.

Must-Have Products:

Wrenches (adjustable and socket sets)

Screwdrivers (flathead, Phillips, etc.)

Pliers and cutters

Hammers and mallets

Investing in high-quality, durable hand tools ensures that your maintenance team can complete their tasks efficiently and safely.

3. Safety Gear and Personal Protective Equipment (PPE)

Why It’s Essential: Safety should always be a priority in the workplace, especially in industrial environments. PPE protects workers from potential injuries, including cuts, burns, electrical hazards, and chemical exposure. Ensuring that your maintenance team is properly equipped with safety gear can prevent accidents and enhance productivity.

Must-Have Products:

Safety gloves (cut-resistant, heat-resistant, or nitrile)

Safety goggles or face shields for eye protection

Hard hats to protect against falling objects

High-visibility vests and clothing for workers in low-light conditions

By maintaining an adequate supply of safety gear, you can keep your team safe while ensuring compliance with workplace regulations.

4. Electrical Supplies

Why It’s Essential: Electrical issues are among the most common causes of machinery malfunction. Having the right electrical supplies on hand allows maintenance teams to troubleshoot and repair electrical systems quickly, minimizing downtime.

Must-Have Products:

Electrical wiring, cables, and connectors

Circuit breakers and fuses

Electrical tape for insulation

Multimeters and voltage testers

These tools help ensure that your factory’s electrical systems are running smoothly and safely.

5. Fasteners and Hardware

Why It’s Essential: Fasteners and hardware are used in nearly every aspect of machinery maintenance and assembly. Whether you’re securing parts, fixing broken components, or assembling new machinery, having the right fasteners is crucial.

Must-Have Products:

Assorted nuts, bolts, and screws

Washers, anchors, and rivets

Threaded rods and fasteners

Strapping and clamps

These small but essential items ensure that your equipment stays securely in place and functions properly.

6. Cleaning and Degreasing Products

Why It’s Essential: Regular cleaning and maintenance of machinery and workspaces is necessary to prevent the buildup of dust, debris, and oils that can cause machines to overheat or malfunction. Cleaning and degreasing supplies help remove dirt, grease, and contaminants that may affect the performance of your equipment.

Must-Have Products:

Industrial degreasers for removing stubborn oils and grease

Solvents for cleaning machinery parts and tools

Shop towels and rags for wiping down surfaces

Pressure washers for cleaning large equipment or floors

Regular cleaning not only keeps machinery in good condition but also creates a safer work environment by reducing hazards like slips or fire risks.

7. Measuring and Testing Instruments

Why It’s Essential: Accurate measurements and testing are key to ensuring that machinery is operating as it should. Having the right instruments allows maintenance teams to troubleshoot problems and perform preventative maintenance before small issues become major failures.

Must-Have Products:

Calipers and micrometers for precise measurements

Torque wrenches for accurate tightening of fasteners

Pressure gauges for pneumatic or hydraulic systems

Thermometers for temperature monitoring

Regular measurement and testing help identify wear and tear or inefficiencies in machinery before they lead to costly breakdowns.

8. Sealants, Adhesives, and Tapes

Why It’s Essential: Sealants, adhesives, and tapes are versatile products that provide essential sealing, bonding, and protective functions in maintenance and repairs. Whether you’re fixing a leak, sealing gaps, or insulating cables, these materials can help improve machine performance and safety.

Must-Have Products:

Thread sealants for pipe repairs

Silicone sealants for waterproofing

Electrical tapes for insulating wires

Double-sided tapes for mounting and securing parts

Having a range of sealants and adhesives ensures that you can quickly address any temporary or permanent repairs without delay.

9. Ladders and Scaffolding

Why It’s Essential: In any factory or industrial setting, maintenance work often requires access to elevated areas or hard-to-reach spaces. Ladders and scaffolding are essential for safely reaching high equipment or performing repairs on elevated surfaces.

Must-Have Products:

Step ladders for quick access to lower heights

Extension ladders for higher-reaching tasks

Scaffolding systems for large-scale projects

Lifting platforms for elevated work on machinery

Properly maintained ladders and scaffolding ensure that maintenance teams can access elevated equipment safely without compromising their well-being.

10. Power Tools

Why It’s Essential: For more heavy-duty tasks, power tools are invaluable in speeding up the repair process and increasing efficiency. From cutting and grinding to drilling and polishing, power tools make demanding tasks more manageable.

Must-Have Products:

Drills and impact drivers for fast, precise work

Angle grinders for cutting or grinding metal

Cordless saws for quick and easy cutting

Electric sanders for smoothing surfaces

Power tools enhance the capabilities of your maintenance team, allowing them to handle more complex tasks with greater efficiency.

Conclusion

By ensuring that your factory is stocked with these 10 must-have MRO supplies, you can help keep operations running smoothly and avoid unnecessary downtime. From lubricants and hand tools to electrical supplies and safety gear, each of these items plays a crucial role in maintaining the safety, efficiency, and longevity of your machinery.Investing in quality MRO supplies and making sure your team has access to the right tools at the right time is not just a smart operational decision—it’s also an investment in the productivity and safety of your factory. Properly maintaining your equipment will not only save you money in the long run but also keep your workforce safe and your production lines running at full capacity.

Add comment